Emulsified asphalt is mainly used for road upgrades and maintenance. Such as sealing layer of stone chips, as well as a variety of unique, irreplaceable other bituminous materials applications, such as cold mix asphalt, slurry seal. Emulsified asphalt can be used for new road construction, such as a sticky layer of oil, transparent layer of oil.

Specification:

|

Model |

Bitumen Emulsion Plant |

|

Bitumen Emulsion Type |

10-60% Ordinary emulsified asphalt production

30-60% modified emulsified asphalt (latex type)

30-40% emulsified SBS modified asphalt (except for emulsified SBS modified asphalt) |

|

Productivity |

customized |

|

Emulsification fineness |

<5um over 90﹪ |

|

Advantages |

1. Whole type unit, easy to install and move, simple operation, cost-effective

2. Emulsifier and other materials through emulsion deployment system

3. Bitumen, emulsion ratio automatic control, operation with protection functions, real-time automatic and accurate adjustment of solid content

4. Corrosion-resistant design, emulsifier and all soap flow components are stainless steel or PPR |

|

Application |

(SBR latex modified or SBS modified high viscosity emulsified bitumen), through-layer spray, slurry seal layer, micro-surface (solid content of more than 63% modified emulsified asphalt ), Cold mix, cold regeneration and so on |

Control system

Using intelligent central control system, with automatic, manual control "oil-water ratio", production and all motor start and stop, protection and other functions

Using intelligent central control system, with automatic, manual control "oil-water ratio", production and all motor start and stop, protection and other functions Milling machine from the most famous manufacturer in China.

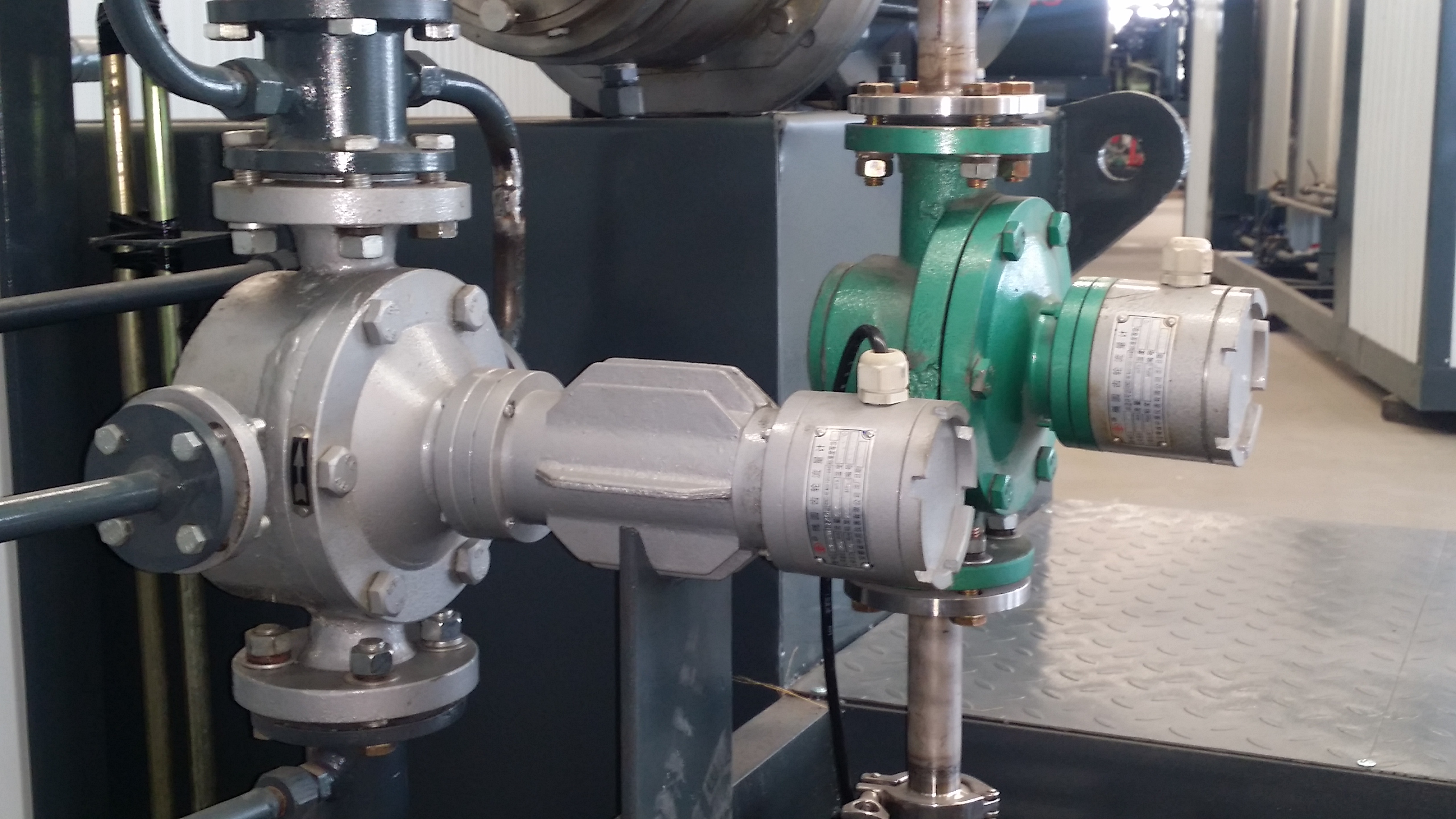

Milling machine from the most famous manufacturer in China. Emulsion pump material is 304 stainless steel, multi-stage type pump, high pump distance, corrosion resistance. Flow range 3-7m³ / h

Emulsion pump material is 304 stainless steel, multi-stage type pump, high pump distance, corrosion resistance. Flow range 3-7m³ / h High precision connected to PLC

High precision connected to PLC