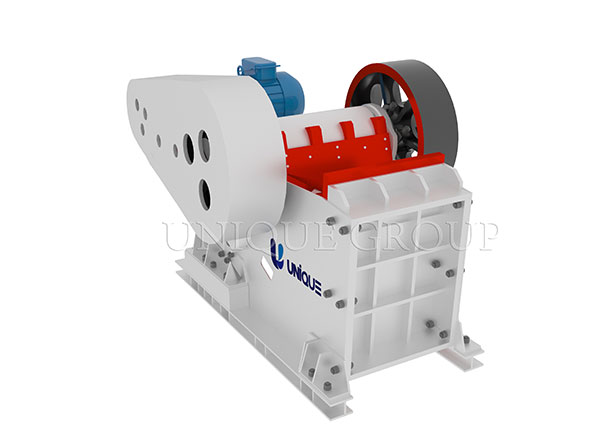

Crushing material:limestone, granite, cobble, dolomite, bluestone, iron ore, construction waste, glass, cement clinker, etc

Applied field:This crusher widely used in quarry, mining, coal, aggregate, sand making, concrete recycle

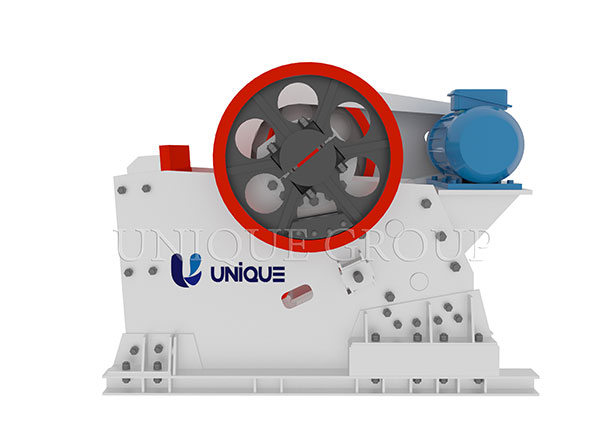

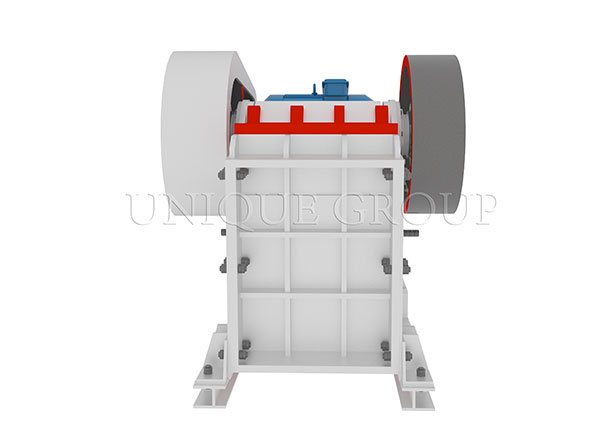

Jaw Crusher is ideally suitable for primary and secondary crusher for material with compression strength less than 320MPA. Jaw Crusher is of high crushing ratio, larger capacity, well-distributed final product size, simple structure, reliable performance, convenient maintenance, lower operation cost, etc. It is widely used in mining, metallurgy, construction, highway, railroad, and water conservancy, etc. Coarse Jaw crusher usually used be primary crusher in stone crusher plant.Jaw crusher is Called panga pandurog sa pilipinas, bato pandurog para ibenta sa pilipinas.

Features and Benefits of Jaw Crusher:

1,Discharge opening of the jaw crusher is adjustable reliably within a wide range through the stuffing of shim, thus it is capable to meet various requirements of customers

2,lubrication system of it is safe and reliable, which boasts an easy and convenient maintenance

3,simple structure, reliable performance, low maintenance cost

4,little dust and low noise

Jaw crusher can crush many materials, such aslimestone, granite, cobble, dolomite, bluestone, iron ore, construction waste, glass, cement clinker, etc. it is widely used in quarry, mining, coal, aggregate, sand making, concrete recycle.Jaw crusher is Called panga pandurog sa pilipinas, bato pandurog para ibenta sa pilipinas.

| Model |

Max feeding Size (mm) |

Adjusting range of discharge opening(mm) |

Capacity (t/h) |

Motor power (kw) |

Total weight (t) |

Dimensions (L*W*H)(mm) |

| PE-150*250 | 125 | 10-40 | 1-3 | 5.5 | 0.8 | 720*660*850 |

| PE-250*400 | 210 | 20-60 | 5-20 | 15 | 2.8 | 1300*1090*1270 |

| PE-400*600 | 340 | 40-100 | 16-60 | 30 | 7 | 1700*1732*1653 |

| PE-500*750 | 425 | 50-100 | 40-110 | 55 | 12 | 2150*1860*2145 |

| PE-600*900 | 500 | 65-180 | 50-180 | 55-75 | 17 | 2792*2168*2250 |

| PE-750*1060 | 630 | 80-180 | 110-320 | 90-110 | 29 | 3100*2400*2950 |

| PE-870*1060 | 750 | 170-270 | 218-353 | 90-110 | 33 | 3200*2400*2950 |

| PE-900*1200 | 750 | 95-255 | 220-450 | 110-132 | 52 | 3380*2870*3330 |

| PE-1000*1200 | 850 | 195-280 | 315-500 | 110-132 | 55 | 3480*2876*3330 |

| PE-1200*1500 | 1020 | 150-300 | 400-800 | 160 | 100.9 | 4200*3300*3500 |

| PEX-150*750 | 120 | 18-48 | 8-25 | 15 | 3.8 | 1200*1530*1060 |

| PEX-250*750 | 210 | 25-60 | 13-35 | 22 | 5.5 | 1400*1617*1412 |

| PEX-250*1000 | 210 | 25-60 | 16-52 | 30-37 | 7 | 1560*1950*1390 |

| PEX-250*1200 | 210 | 25-60 | 20-61 | 37-45 | 8.7 | 1530*2192*1380 |

| PEX-300*1300 | 250 | 20-90 | 25-95 | 55-75 | 11.6 | 1930*2400*1747 |

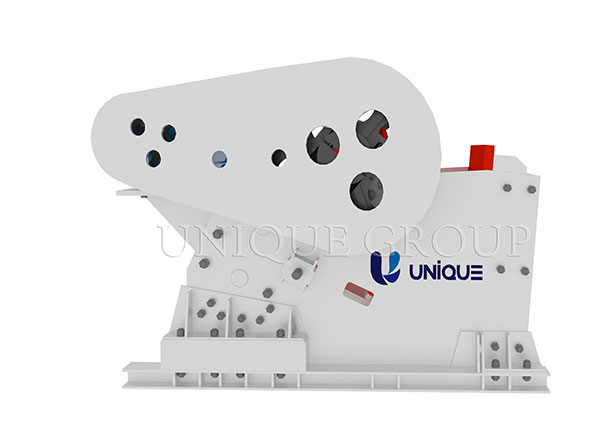

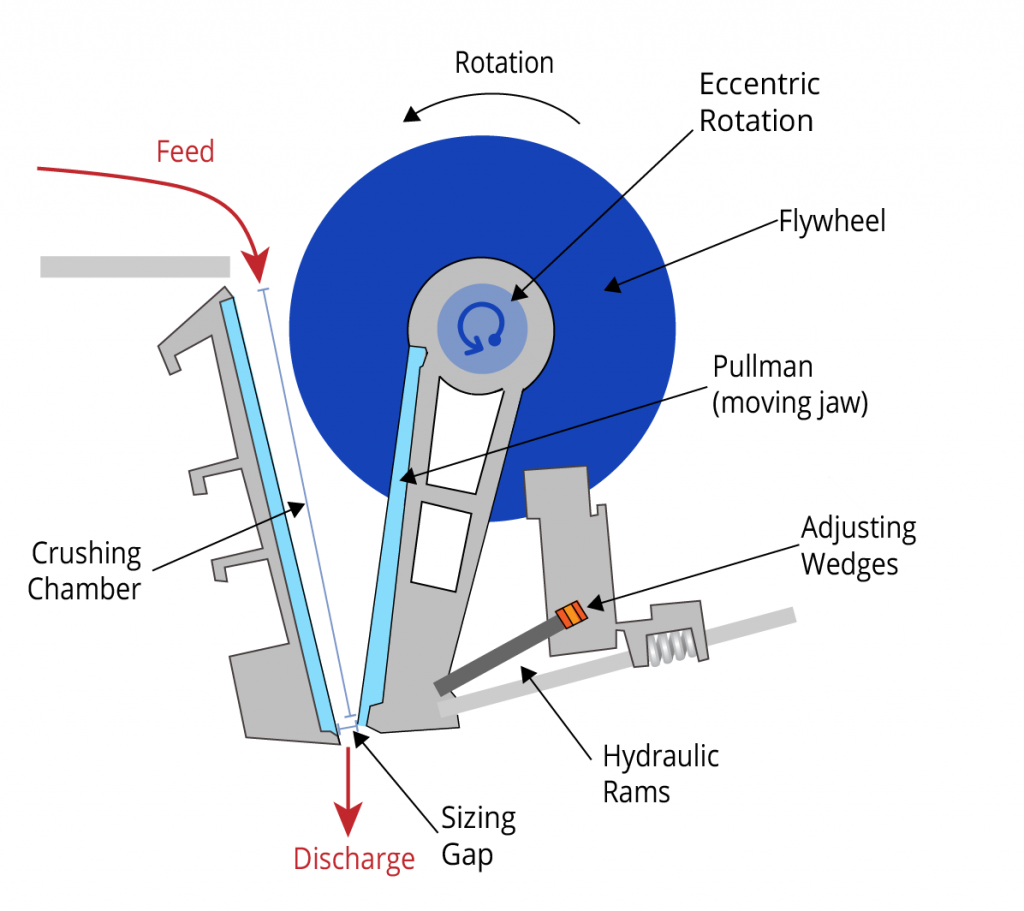

Operating Principle of Jaw Crusher:

The electrical motor transmits power to the eccentric shaft through v-belt and belt pulley. Then the exciting force generated by the eccentric shaft will make the movable jaw move upwards and downwards. This movement would trigger the toggle plate to push the movable jaw forwards and backwards. When the movable jaw moves forth towards the fixed jaw, materials in the crushing cavity will be squashed or chopped. And then the movable jaw travels back, the chopped or squashed materials which meet the requirement will be discharged from the outlet. Since the motor keeps working. The crusher will crush and discharge periodically to achieve mass production.

Jaw crusher is Called panga pandurog sa pilipinas, bato pandurog para ibenta sa pilipinas.